Challenges and Solutions

In the Energy & Environmental sector, companies face the challenge of developing plants and equipment that operate efficiently under extreme conditions, have a long lifespan, and are simultaneously environmentally friendly and sustainable.

Efficiency

Stainless steel ensures smooth processes due to its corrosion resistance and low wear.

Durability

Stainless steel withstands high temperatures, pressure, and aggressive media, thereby extending the lifespan of the equipment.

Environmental Compatibility

Stainless steel is 100% recyclable and contributes to an environmentally friendly and resource-conserving production.

Innovations for the Highest Demands in the Energy & Environmental Sector

The Energy & Environmental sector places the highest demands on materials and technologies to ensure efficiency, durability, and environmental compatibility. Our stainless steel solutions go far beyond standard applications and significantly contribute to the optimization of plants and equipment in this sector.

Through continuous development and years of experience, we offer innovative solutions that meet the current and future challenges in energy generation, distribution, and environmental protection. With a clear focus on sustainability, resilience, and utmost precision, we support the sector in advancing environmentally friendly and efficient technologies.

Our Product Range

Our portfolio includes a variety of solutions for the Energy & Environmental sector

-

Filter Housings

In an extensive development phase, we have set standards with cartridge filter housings and modular filter housings. Whether different sizes, diverse connection options, innovative functions and features, or special housings directly according to specific customer requirements - we ensure that you receive customized products according to your specifications.

-

Modular systems

Modular systems for a renewable future, completion of 20" containers, e.g., for a plant that will produce 4.2 million liters of synthetic fuel.

-

MEMBRANE HOUSING

Our MembraLine® membrane housings are suitable for membrane elements from microfiltration to 160-bar high-pressure reverse osmosis, ensuring you reliable filtration.

We also manufacture stainless steel components that can accommodate membranes from 1.8″ to 8.3″. With our modular system, it is possible to individually configure suitable housings and assemble them from standard parts.

-

Heat Exchanger

Our HexaLine heat exchangers, for which we handle not only the design and manufacturing but also the thermal calculation for our customers, are available as double-pipe heat exchangers and shell-and-tube heat exchangers, also available on a skid.

-

Containers

We have 50 years of experience in manufacturing pressure vessels, process vessels, agitator vessels, and storage tanks made of stainless steel. With a volume of up to 1,500 l, with heating or cooling jacket, insulation jacket, agitator, or bottom outlet valve — you make the decision according to your requirements. The execution of the containers is carried out according to AD2000, EN13445, or ASME with worldwide acceptance possibilities.

-

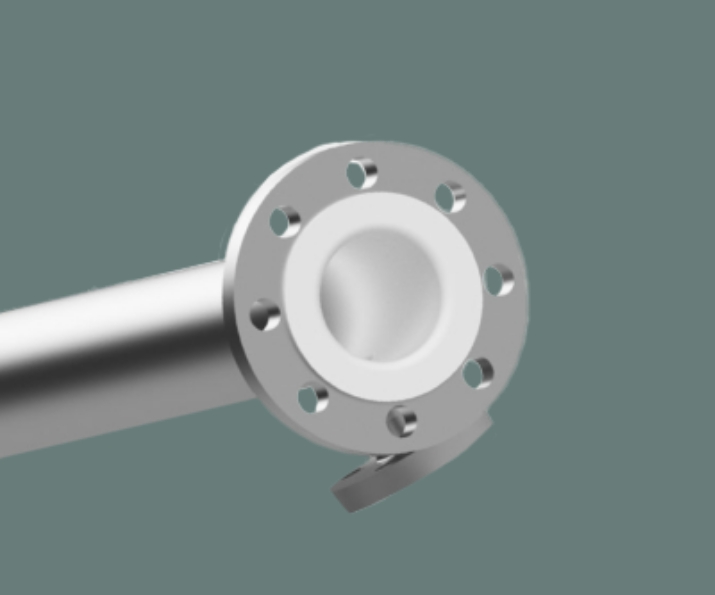

RESILINE® PRESSURE PIPES

Our ResiLine® pressure pipes are suitable whenever aggressive media are used. The corrosion-resistant lining allows for versatile use in different areas. The ETFE-coated pressure pipes offer an attractive price-performance ratio compared to pure special materials. This is made possible by an ETFE coating, which is applied through a rotational lining process and ensures a permanent bond between stainless steel and polymer coating.

-

Branch Pipes

With our branch distributors and collection pipes, we have the opportunity to ensure a rational and hygienic plant construction.

We develop pipe branchings that are mechanically formed using special tools. With the innovative solutions, it is possible to design a rational and hygienic plant or pipeline construction.