Challenges and Solutions

In the Food & Beverage industry, materials must meet the highest standards of safety, hygiene, and efficiency to ensure the quality and sustainability of food production in the long term.

Safety and Hygiene

Stainless steel is corrosion-resistant, easy to clean, and meets the highest hygiene standards.

Durability

Stainless steel offers high resistance to mechanical stress and aggressive cleaning agents.

Efficiency

Stainless steel reduces maintenance effort, ensures a long service life of the equipment, and optimizes production processes.

-

MEMBRANE HOUSING

Our MembraLine® membrane housings are suitable for membrane elements from microfiltration to 160-bar high-pressure reverse osmosis, ensuring you reliable filtration.

We also manufacture stainless steel components that can accommodate membranes from 1.8″ to 8.3″. With our modular system, it is possible to individually configure suitable housings and assemble them from standard parts.

-

INEX MICRO AND NANOPLASTIC FILTRATION SYSTEM

Clean drinking water for everyone – with our compact stainless steel system developed in Germany, we are setting new standards in water treatment. The adsorptive process removes micro and nanoplastic particles down to < 2 nanometers with an efficiency of 99%.

The adsorptive process uses a regenerative, recyclable smart-surface technology, whose effectiveness has been validated by eight independent laboratories with over fifty tested types of plastic. Micro and nanoplastic particles are adsorbed through biochemical-molecular forces and can subsequently be recycled.

Together with our partner Klar2O, your individual requirement is simulated in the laboratory, resulting in a tailored and practice-oriented solution for every application.

Areas of application: Drinking water and bottling plants in the beverage industry, municipal waterworks and treatment plants, as well as pharmaceutical, energy, and industrial companies with their own need for micro and nanoplastic-free process water. -

Filter Housing FiltraLine®

With our FiltraLine® filter housings, we meet the highest demands of filtration and support you with more than 50 years of experience in stainless steel processing to meet the individual tasks of your industry.

In a comprehensive development phase with cartridge filter housings, bag filter housings, and module filter housings, we have set a standard. Whether different sizes, various connections, innovative functions and features, or special housings according to specific customer requirements – we ensure that you receive customized products that align with your expectations.

-

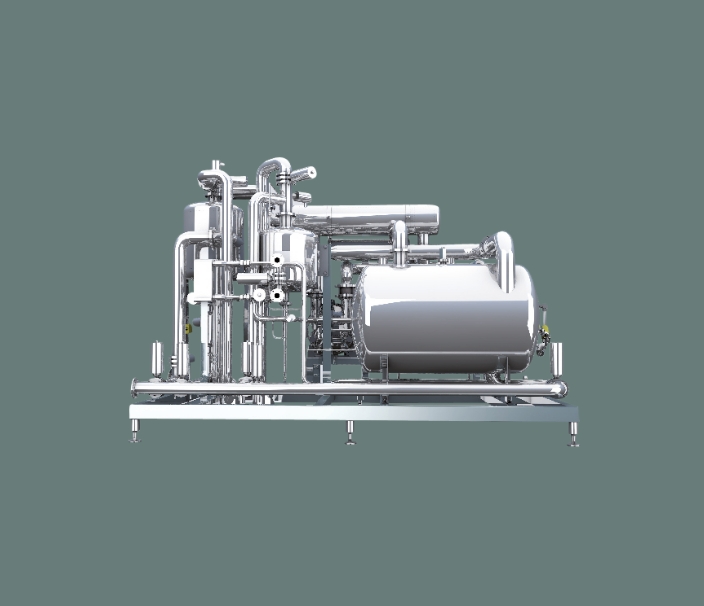

Heat Exchanger

Our HexaLine heat exchangers, for which we take care of the design, manufacturing, and thermal calculation for our customers, are available as double-pipe heat exchangers and shell-and-tube heat exchangers, also available on a skid.

-

Containers

We have 50 years of experience in manufacturing pressure vessels, process containers, agitator vessels, and storage tanks made of stainless steel. With a volume of up to 1,500 l, with heating or cooling jacket, insulation jacket, agitator, or bottom outlet valve — you make the decision according to your requirements. The execution of the containers is carried out according to AD2000, EN13445, or ASME with worldwide acceptance possibilities.

-

SCALES

Functionality and design complement each other in this scale made entirely of stainless steel. The perfect finish is a specialty of Hubl Edelstahltechnik. Thus, rounded edges in the handling area and the absolutely burr-free processing of the assembly ensure that no residues and germs can settle.

-

PLANT CONSTRUCTION

Our plant construction enables us to erect structures up to eight meters high and realize frame constructions with stairs and railings.

Manufacture of pipelines from selected materials such as Hastelloy, Duplex, coated pipes, etc. Specific tests, such as material mix-up (XRF), X-ray, dye penetrant testing, or on-site pressure testing possible Endoscopic inspection & documentation by VT inspector (filming or photographing possible) Manufacturing according to the technical standard ASME B31.3. Extensive approvals and certificates FAT or remote-FAT. -

FILTRALINE® MODULE FILTER

With our FiltraLine® module filter, we impress with a well-thought-out design of up to six lens modules arranged on top of each other and an externally adjustable contact pressure on the modules.

Unbeatable when efficient filtration and separation of fluids, liquids, and gases must be ensured. Whether in the food, pharmaceutical, or chemical sectors, our module filters in the 12" or 16" versions are available with either a flat-sealing or double O-ring connection. We also manufacture our innovative FiltraLine® module filters according to customer requirements and filtration tasks, with regard to material selection and module heights.

-

Branch Connections

With our branched distributors and manifolds, we have the opportunity to ensure a rational and hygienic plant construction.

We develop pipe branches that are mechanically formed using special tools. With the innovative solutions, it is possible to design a rational and hygienic plant or pipeline construction.