Innovations for the Highest

Standards in Healthcare

The life sciences sector constantly requires innovative solutions to meet the increasing demands regarding hygiene, safety, and durability. Our stainless steel technologies go far beyond standard solutions and set new benchmarks in the production of medical devices and pharmaceutical equipment.

Meeting the high quality standards of life science components often leads to significant challenges. This is exactly where we are here for you! Whether it's dead space-free designs, the highest surface finishes, or extensive documentation, with us, you will master every requirement.

-

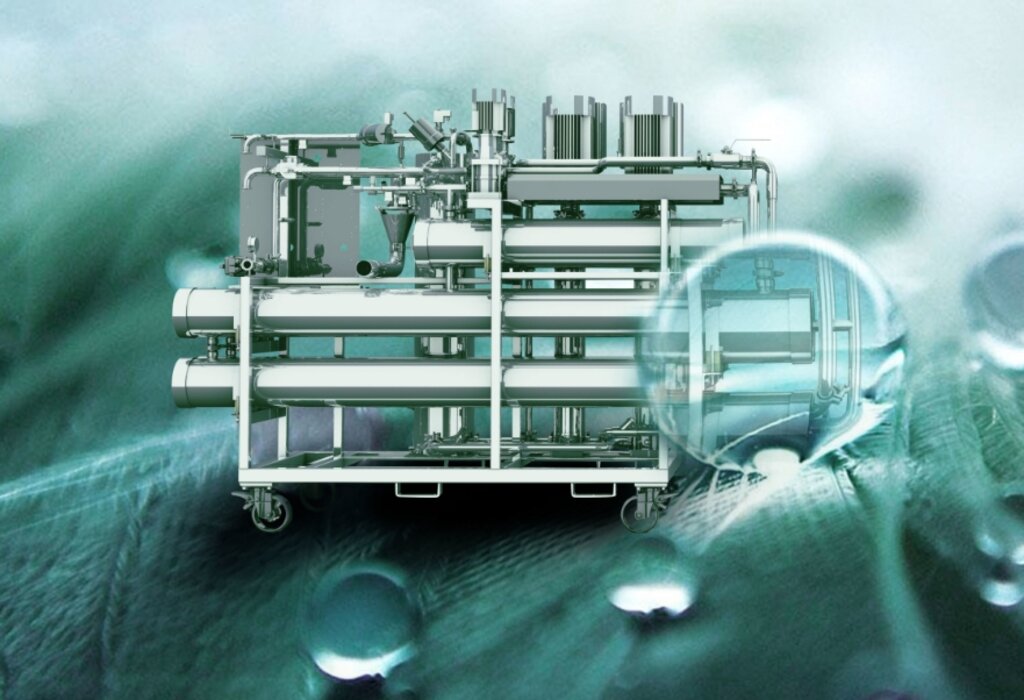

PLANT CONSTRUCTION

Our plant construction enables us to erect structures up to eight meters high and realize frame constructions with stairs and railings.

Manufacture of pipelines from selected materials such as Hastelloy, Duplex, coated pipes, etc. Specific tests, such as material mix-up (XRF), X-ray, dye penetrant testing, or on-site pressure testing possible Endoscopic inspection & documentation by VT inspector (filming or photographing possible) Manufacturing according to the technical standard ASME B31.3. Extensive approvals and certificates FAT or remote-FAT. -

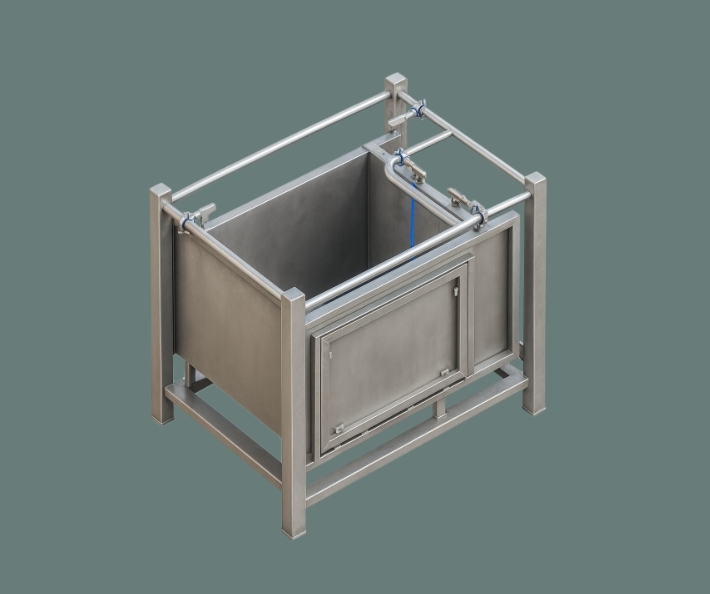

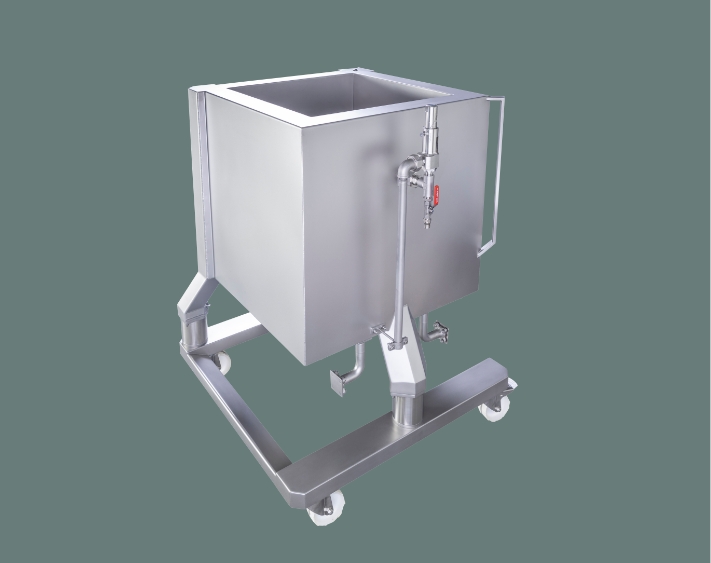

AGNOTAINER

With the patented HUBL Agnotainer, the variety of stainless steel shipping and storage tanks available on the market is reduced to one container per volume class (100 l, 200 l, 500 l, 1000 l). The HUBL Agnotainer adapts optimally to all common single-use bioprocess bag sizes. Stackability, flexible port positions, corrosion protection, and a GMP-compliant stainless steel surface characterize the new HUBL Agnotainer generation.

-

Stainless Steel Housing

Functional high-quality stainless steel housings meet the core competence of Hubl Edelstahltechnik. Here, housings with pump and dosing facilities as well as the casing of a control unit with display mount for laboratory technology are executed in stainless steel with rounded edges and seals in IP standard, fulfilling the highest requirements in terms of function and design.

-

MEMBRANE HOUSING

Our MembraLine® membrane housings are suitable from microfiltration to 160-bar high-pressure reverse osmosis and guarantee you reliable filtration.

We also manufacture components made of stainless steel that can accommodate membranes from 1.8″ to 8.3″. With our modular system, it is possible to individually configure suitable housings and assemble them from standard parts.

We have created an innovation in the MembraLine® product group with our ETFE-coated ResiLine® membrane housing, which is used for highly corrosive media.

-

FiltraLine® Cartridge Filter Housings

With our FiltraLine® cartridge filter housings, we offer specific housings as well as standardized series. Tailored to your specific requirements.

When it comes to the filtration and separation of fluids, liquids, and gases, our FiltraLine® cartridge filter housings are the first choice for numerous filtration tasks in the food, pharmaceutical, and chemical industries. The high quality of the materials and precise manufacturing ensure a long service life. Additionally, the housings are modularly adaptable to different filter cartridge lengths. Just a few of the advantages of our FiltraLine® cartridge filter housings.

-

FILTRALINE® MODULE FILTER

With our FiltraLine® module filter, we impress with a well-thought-out design of up to six lens modules arranged on top of each other and an externally adjustable contact pressure on the modules.

Unbeatable when efficient filtration and separation of fluids, liquids, and gases must be ensured. Whether in the food, pharmaceutical, or chemical sectors, our module filters in the 12" or 16" versions are available with either a flat-sealing or double O-ring connection. We also manufacture our innovative FiltraLine® module filters according to customer requirements and filtration tasks, with regard to material selection and module heights.

-

Containers

With the production of pressure vessels, process containers, bioreactors, fermenters, agitator vessels, and storage tanks made of stainless steel, we can meet the specific requirements in life sciences. We ensure through custom manufacturing that a customer-specific application becomes possible. With a volume of 1.5 l to 1,500 l, with heating or cooling jacket, insulation jacket, agitators, or bottom outlet valves, you make the decisions according to your requirements. The execution of the containers is carried out according to AD2000, EN13445, or ASME with worldwide acceptance possibilities.

-

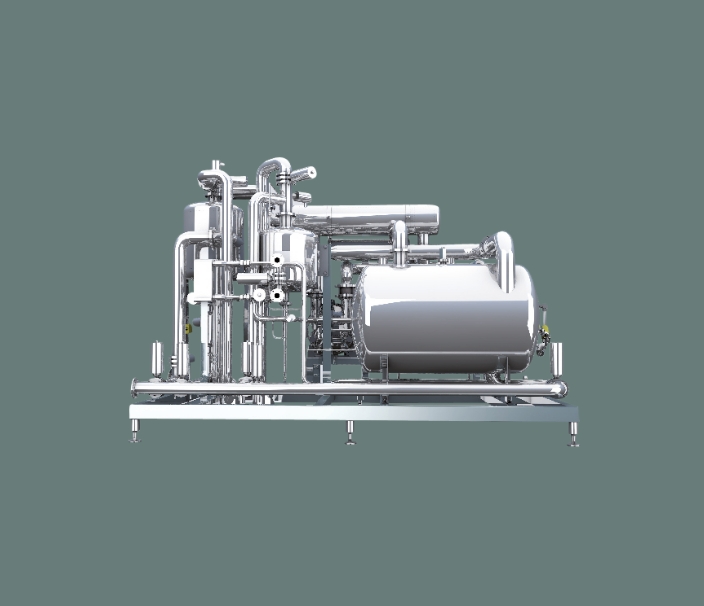

STORAGE AND PROCESS CONTAINERS

This storage and process container was manufactured considering customer-specific surface specifications and Ra values. The integrated heat exchanger was developed by the engineers at Hubl Edelstahltechnik.

Through highly precise stainless steel manufacturing and intelligent fluid management, impressive heat transfer performances can be achieved with significantly less flow rate.

-

Branch Pipes

With our branched distributors and manifolds, we have the ability to ensure a rational and hygienic plant construction.

We develop pipe branchings that are mechanically formed using special tools. With the innovative solutions, it is possible to design a rational and hygienic plant or pipeline construction.

-

HexaLine Heat Exchanger

From the analysis of process data to the finished product, we handle all steps for the customization of components.

With our HexaLine heat exchanger (Pharma DTS heat exchanger), we are by your side from the thermal design to the delivery of the finished heat exchanger. Our double-tube heat exchangers impress with a simple and compact design, while the shell-and-tube heat exchanger is ideally suited for high flow rates and/or demanding heat transfer tasks with a multitude of thin inner tubes.